Economic Briquetting Plant

The first model developed by us that set off our journey of technological excellence and innovation is SUPER 65 MODEL. This Economic Briquetting Plant model is supported by Hammer mill to convert raw material into powder form before it is processed to produce bio-mass briquettes. This model is best suitable for achieving medium production capacity with minimum capital expenditure.

Medium Briquetting Plant

Our SUPREME 75 MODEL is the ideal choice of the manufacturers looking for output in the range of 750-1000 kg/hr. and not yet ready for the investment in installation of JUMB0 BRQ 9075 MODEL. This Medium Briquetting Plant machine is also supported by Hammer Mill that breaks raw material in powdery form that is suitable for final process of bio-mass production.

Giant Briquetting Plant

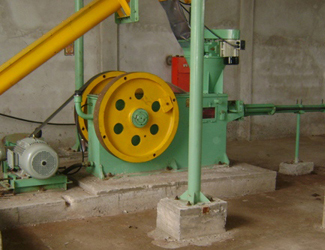

The most outstanding and flagship products from our Giant Briquetting Plant products portfolio have been JUMBO BRQ 9075 MODEL armed with cutting technology and engineered to deliver maximum output. Certain innovations made in its design and production make it exceptionally cost effective and technically superior.

Customized Briquetting Plant

Briquetting press is where the raw material of required size in fed into tough taper die through screw conveyor. Due to heat and high pressure raw material in the form of powder gets converted into solid cylindrical shaped briquettes. In Customized Briquetting Plant this process lignite content of all raw materials gets converted into liquid due to heat and pressure and this liquid content acts as binder. So in this technology no external source of binding is required to form the cylindrical shape if briquettes. Therefore this technology is known as binder less technology.

Powder Making Plant For Briquetting

Powder making unit being the integral part of SUPER 65 and SUPREME 75 models, let’s understand the compositions of these briquetting plant models.

Screw Conveyors suitable for feeding cut or granulated raw materials to Hammer Mill, Dryers, Briquetting machine and Pelletizing machine as the case may be. The equipment is designed for continuous operation and comes with a feeding hopper and controls.

Briquetting Plant Crusher – Shredder

For Chipping and Shredding of Briquetting Plant Crusher biomass Agro & Forestry waste such as Groundnut Shell, Wood Chips, Wood waste, Tree Bark, sugarcane Trash, Palm Waste, Coconut Shell, Cotton stalks etc with maximum moisture content up to 50% and having maximum diameter up to 50 mm.

Briquetting Plant Turbo Dryer

Certain raw materials containing moisture content beyond 45% (wet basis), need to be treated for moisture evaporation to bring the moisture content to acceptable limit of 15%. For suspension drying of fibrous materials like bagasse, jute, coir pith etc., turbo dryer is required.

General Description :

The system consists of screw conveyor, vibrating screen, feeding hopper vane guide, conveying line including insulated drying column and conveying line through which wet or moist material is conveyed with hot air. A powerful low pressure open wheel centrifugal fan assures significant resilience time for removal of excess moistures. Material is conveyed to cyclone and discharged through air tap duct.

Briquetting Plant | Briquetting Plant Manufacturer | Briquetting Plant Supplier | Briquetting Plant Exporter | Briquetting Plant India